According to your needness, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.

According to the forming mechanism, forging can be divided into free forging, die forging, ring rolling and special forging.

1. Free forging. It refers to the processing method of forging which uses simple universal tools or directly applies external force to the blank between the upper and lower anvils of forging equipment to deform the blank and obtain the required geometric shape and internal quality. Forgings produced by free forging method are called free forgings. Free forging is mainly used to produce forgings with small batch. Forging hammer, hydraulic press and other forging equipment are used to shape the blank and obtain qualified forgings. The basic processes of free forging include upsetting, elongation, punching, cutting, bending, twisting, staggering and forging. Free forging adopts hot forging.

2. Die forging. Die forging is also divided into open die forging and closed die forging. The metal blank is compressed and deformed in the forging die chamber with a certain shape to obtain forgings. Die forging is generally used to produce parts with small weight and large batch.

Die forging can be divided into hot forging, warm forging and cold forging. Warm forging and cold forging are the future development direction of die forging, and also represent the level of forging technology.

According to materials, die forging can also be divided into ferrous metal die forging, nonferrous metal die forging and powder product forming. As the name implies, the materials are ferrous metals such as carbon steel, nonferrous metals such as copper and aluminum, and powder metallurgy materials.

Extrusion belongs to die forging, which can be divided into heavy metal extrusion and light metal extrusion.

Closed die forging and closed upsetting are two advanced processes of die forging. Because there is no flash, the utilization rate of materials is high. It is possible to finish complex forgings with one or several processes. Since there is no flash, the force bearing area of the forging is reduced, and the required load is also reduced. However, it should be noted that the blank cannot be completely restricted. For this reason, the volume of blank should be strictly controlled, the relative position of forging die should be controlled and the forging should be measured to try to reduce the wear of forging die.

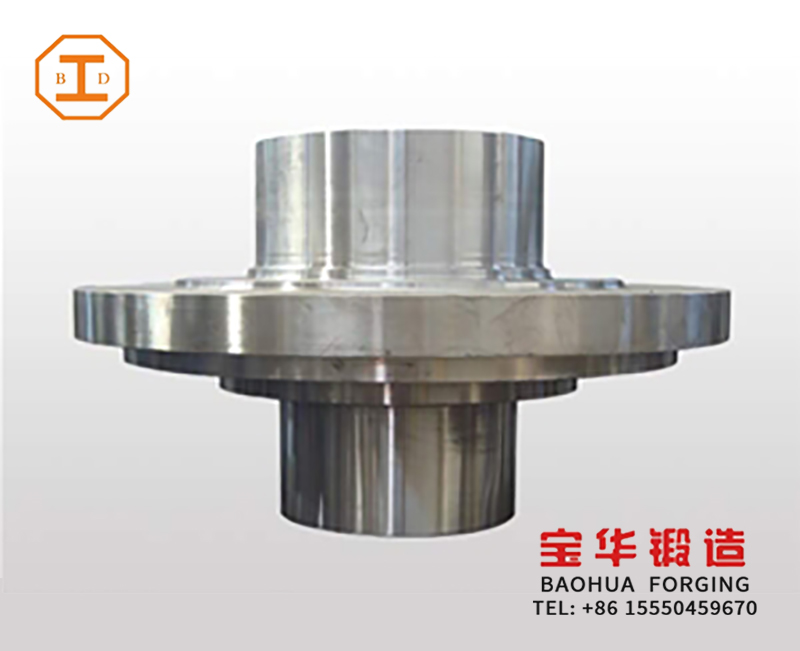

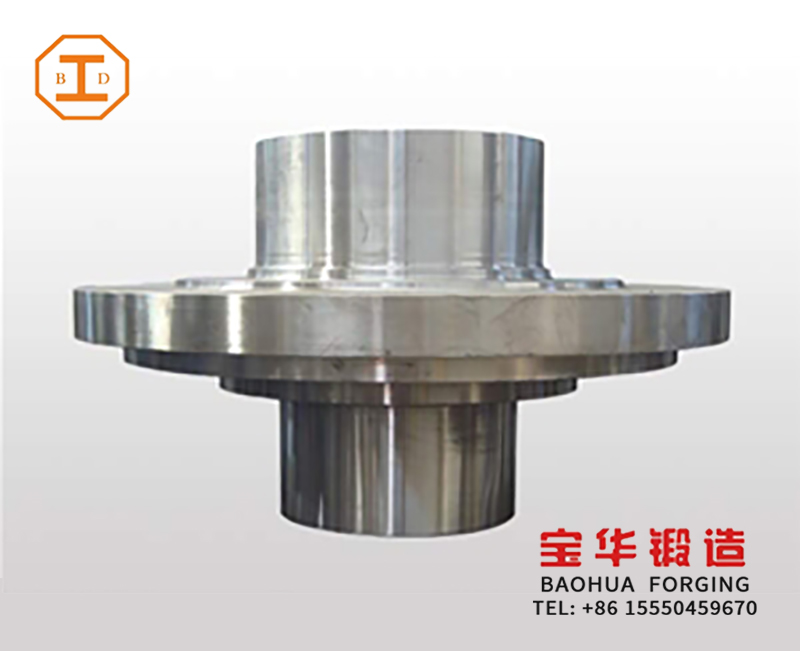

3. Grinding ring. Grinding ring refers to the production of annular parts with different diameters through special equipment ring mill, and also used to produce wheel shaped parts such as car hubs and train wheels.

4. Special forging. Special forging includes roll forging, cross wedge rolling, radial forging, liquid die forging and other forging methods [5], which are more suitable for producing parts with special shapes.

Customers in any industry using gears can request a quote for any quantity of it, from one prototype at a time and small batches to high volume production. Our extensions include gear cutting to finished gear size.